The energy transition is clogging up the electricity grid in a growing number of places. Construction manager at Heijmans, Klaas van der Wiel, and technical manager Johan Mulder of Liander explain how you future proof the power grid.

Klaas pulls open a creaking stable door. We walk past some farm machinery and see a partition wall with windows in the corner to the right. Behind this, we find the office used by Klaas and his team. Today we are in the Frisian village of Sibrandahus, west of Dokkum. Nearby, Heijmans is building a new route for 20,000-volt electricity cables for Liander, between the existing substation in Dokkum and the new control station in Hallum.

The basics

Electricity is a complicated business. So first the basics: how is electricity transported to your home or business? Liander’s Johan Mulder is happy to explain: “Power plants, solar panels and wind turbines generate electricity. A national network of 380, 220 and 110-kilovolt (kV) high-voltage lines transport that power all over the Netherlands. Network operators like Liander transform this high voltage back to 20 or 10 kV, or medium voltage. They then distribute the power over several underground cables that exit at control stations, like the one in Hallum. From there, cables run to local transformer stations, where the power is converted to low voltage. Then an underground cable runs from the transformer station or a switchbox to your house. The cable enters your home in the meter box. From the meter box, electricity cables in your walls and ceilings take 230 volts to all the sockets and switches in your house.”

Rising demand

The use of the electricity network is changing at lightning speed. This has two causes, Johan says. “Consumers and entrepreneurs are increasingly switching from natural gas to electricity and more and more people are driving electric cars.

“The second reason is the transition from electricity production in a few coal and gas-fired power plants to hundreds of thousands of large and smaller renewable generation plants all over the country. Over 1.5 million people now have solar panels on their roofs, and more and more windmill and solar farms are being added at a rapid pace. Most of these are appearing in rural areas. And that is precisely where the thin cables are located, because there was not much demand for electricity in these areas. To meet the new demand, we need to expand the electricity grid considerably. As a grid operator, we have to do the same amount of work in the next 10 years as we have done in the last 40 years.”

Clogged garden hose

A big job, then. Meanwhile, we are seeing frequently media reports on overloaded power grids. Where exactly does the power grid get clogged up? Johan likes to keep his examples practical. “Compare electricity to water flowing through a garden hose. If you squeeze somewhere halfway down the hose, less water comes out. The same principle applies to an electricity cable. Old, thinner cables cannot handle the amount of power demanded. Certainly not at peak moments, when a lot of power is called on or supplied in a short period of time. This causes a ‘traffic jam’ in the power cable, or to use a more difficult word congestion. To prevent overloading, we are reinforcing the existing power grid with more and thicker cables.”

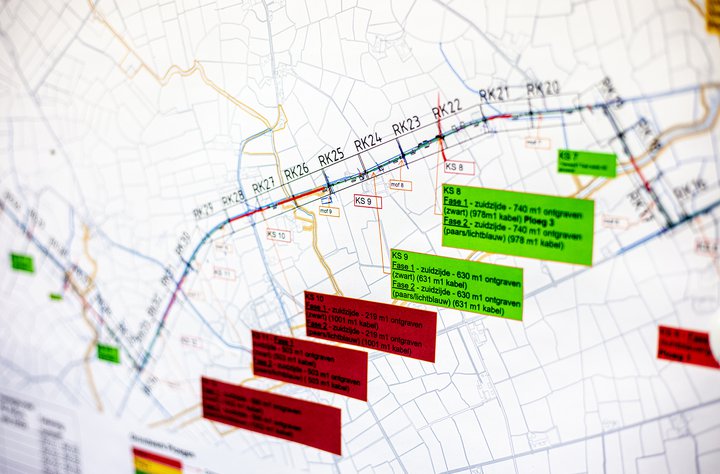

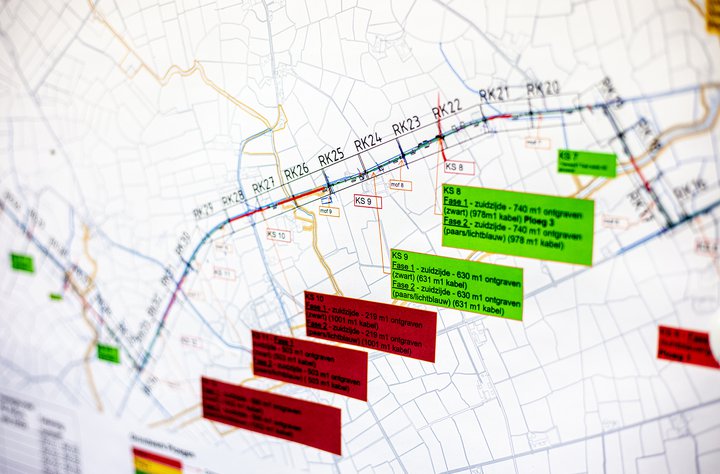

Demand for power around the Frisian town of Hallum has also increased significantly in recent years. “We now supply companies and private individuals with power from our distribution station in Leeuwarden, but the power cable cannot cope with the demand,” says Johan, as his finger glides over the construction drawing. “That’s why we are now laying a new 20,000-volt or 20kV cable between the existing electricity distribution station in Dokkum and the new control station in Hallum.”

Digging and drilling

After a cup of coffee, we leave for the construction site. A broad term, as the total project is over 17.5 kilometres long. We stop in front of a farmhouse. To the left and right, we see two trenches with white tents. At the bottom are three fist-thick red cables. The two ends meet in the little tent. Heijmans construction manager Klaas van der Wiel: “We are laying the new 20-kV cables alongside the old 10-kV cables, as they will remain in use. In total, we are laying more than 200 kilometres of cable in the ground, mostly in trenches. We also have to pass under a road, a waterway or under an old row of trees a total of sixteen times. We do this using Horizontal Directional Drilling (HDD) technology.”

Route study

“My colleagues at Liander headquarters first put together the broad outlines,” Johan continues. “We then make the final design at project level. We prefer to lay our route across public land. Unfortunately, this is not possible everywhere. Which is why contact with the surrounding area is so important, and why we always perform a route study.”

The team deals with dozens of stakeholders, Klaas adds. “We work on land belonging to municipalities, private individuals and water boards. But also in farmers’ fields and meadows. Every excavation or drilling is discussed in detail beforehand and included in the design, but you always come across unexpected situations. For instance, you may come across archaeological finds and existing cables and pipelines. We also have to take in to account wildlife, such as badgers, meadow birds and otters. We don’t excavate at the electricity distribution station, as the risk of a cable fracture is too great. This is why here we dig by hand or use a suction machine. This requires a lot of coordination with the client.”

Sleeves

Connecting the huge electricity cables together is specialist work. “We connect them together using so-called ‘sleeves’. A grain of sand or a tap with a shovel is enough to cause a failure. In such a case, the sleeve is immediately written off and you have to start all over again. You want to avoid these failure costs.” Plugging the trenches is also skilled work. “You can’t just throw a shovel of rubble or earth on a cable. That can damage it.”

Timely action

Developments in the energy market are happening at lightning speed. Rising gas and oil prices are accelerating electrification, Johan thinks. “Still, looking ahead is difficult. It is important for us as a grid operator to know in time which developments are taking place at which time. Such as the arrival of a new residential area or business park. Or entrepreneurs expanding their activities or switching from natural gas to electricity. Fortunately for us, businesses in particular are applying for upgrades to their connections at an increasingly early stage, so we can start designing and planning in time. Because while an entrepreneur can have a new production facility up and running in less than a year, a grid operator often needs several years to prepare the electricity grid for this facility due to prolonged licensing processes and procedures.”

Scarce

On this project, Heijmans is working with several local subcontractors. “Heijmans is only responsible for the execution here, while the rest is outsourced. We are already quite busy with several large cable and pipeline projects in the central and western parts of the country,” says Klaas. “I expect us to be involved in many more such projects in the coming years. Heijmans has all the expertise in-house and can realise both high-voltage and medium-voltage projects. This will be a major challenge, especially as staff are scarce.”

As we drive back to the project office, we see a couple of wind turbines on the horizon, happily making the most of the gathering north-westerly wind. “If all goes well, the project will be completed by summer. Together with Liander, we are conducting a final test of the entire route. If this is successful, Liander will switch on power to the new cables for the new control station in Hallum. And then the grid reinforcement here will be done and dusted!”